19 Nov

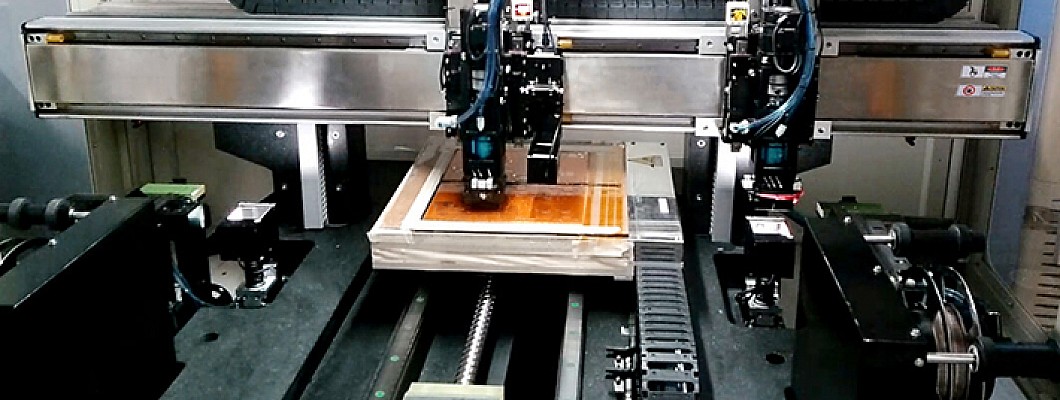

1. What is the load of the system?

The load of the system includes static load and dynamic load, usually the size of the load determines the basic size of the motor.

- Static load: the maximum thrust that the screw can withstand at a static state.

- Dynamic load: the maximum thrust that the screw can withstand when it is in motion.

2. What is the linear operating speed of the motor?

The operating speed of the linear stepper motor is closely related to the lead of the screw, one revolution of the screw means the nut advances one lead. For low speed, it is advisable to choose a screw with a smaller lead, while for high speed, it is advisable to choose a larger screw.

3.What is the accuracy requirement of the system?

- Screw accuracy: the accuracy of the screw is generally measured by the linear accuracy, i.e. the error between the actual travel and the theoretical travel after a number of turns of the screw.

- Repeat positioning accuracy: repeat positioning accuracy is defined as the accuracy of the system to be able to reach the specified position repeatedly, which is an important indicator for the system.

- Backlash: The amount of relative movement available in the axial direction between the screw and the nut when the backlash is stationary. As the working time increases, the backlash will also increase due to wear. Compensation or correction of backlash can be achieved by a backlash eliminating nut. When bi-directional positioning is required, backlash is a concern.

4. Other aspects

The following questions also need to be considered when selecting a stepper motor linear actuator:

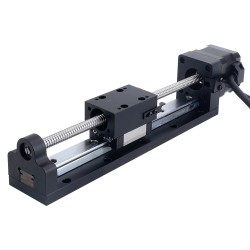

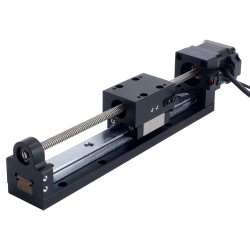

- Is the mounting of the linear stepper motor in accordance with the mechanical design?

- How will you attach the moving object to the nut?

- What is the effective stroke of the screw rod?

- What kind of drive will be matched?