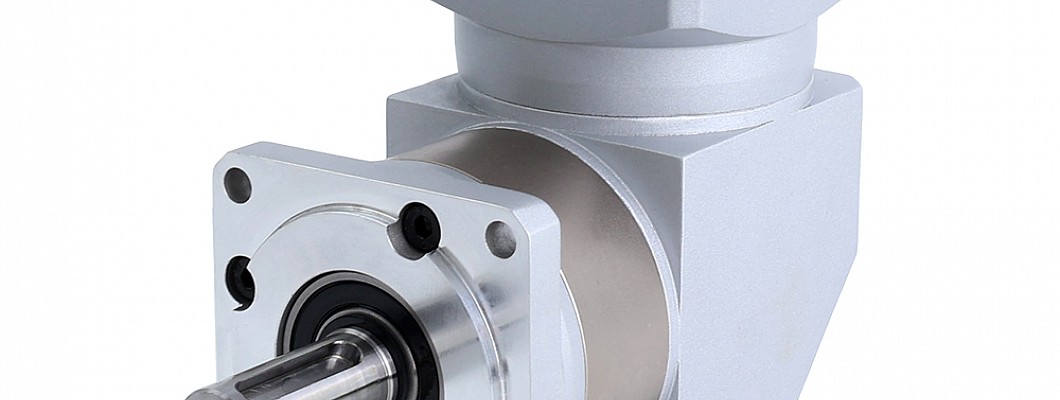

The right angle gearbox is a transmission device composed of two mutually perpendicular shafts and a set of gears, in which the input torque of one shaft is transmitted to the other shaft. The right angle gearbox usually consists of a worm, worm wheel, worm wheel bearing, output shaft, and gears.

The advantages of a right angle gearbox are as follows:

High transmission efficiency: The right angle gearbox adopts gear transmission, which has high transmission efficiency and can effectively reduce energy loss.

Good stability: The internal gear transmission of the right angle gearbox has many teeth, low noise, and smooth transmission, which can ensure transmission accuracy and stability.

Compact structure: The structure of the right angle gearbox is compact, which can effectively save space and is suitable for installation in limited space.

Large transmission ratio: The transmission ratio of the right angle gearbox is usually between 1:1 and 1:5, which has a large transmission ratio and can meet the transmission requirements of different occasions.

There are also some disadvantages to using these gearboxes. Here are a few:

Limited speed range: Right angle gearboxes are not suitable for high-speed applications due to their design and construction. The bevel gears inside the gearbox generate more heat and noise at higher speeds, which can cause wear and tear on the gears and reduce their lifespan.

Higher cost: Right angle gearboxes are more expensive than other types of gearboxes due to their complex design and manufacturing process. This can make them less attractive for budget-conscious applications.

Reduced efficiency: Due to the nature of their design, right angle gearboxes can experience higher friction losses than other gearboxes. This results in reduced efficiency, which can lead to increased power consumption and reduced performance.

Limited input and output options: Right angle gearboxes typically have limited input and output options, which can limit their versatility and application range. For example, they may not be suitable for use with certain types of motors or equipment.

Maintenance requirements: Right angle gearboxes require regular maintenance and lubrication to ensure proper functioning and prevent damage. This can add to the cost and complexity of their use.

Wide range of applications: The right angle gearbox can be widely used in various mechanical equipment, such as industrial production, agricultural machinery, construction machinery, aerospace, automobiles, and other fields.

In summary, the right angle gearbox has the advantages of high transmission efficiency, good stability, compact structure, large transmission ratio, and wide range of applications, making it a widely used transmission device.