19 May

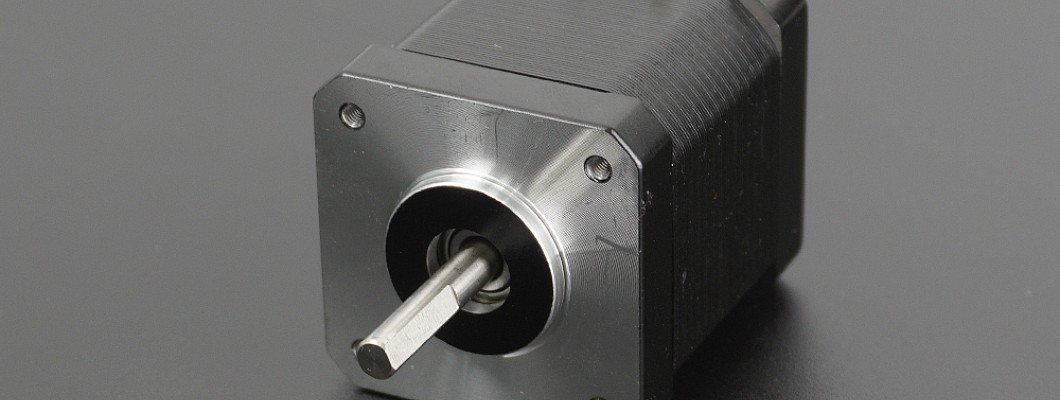

Abstract: The biggest difference between stepper motors and other control motors is that stepper motors are controlled by inputting pulse signals. It receives digital control signals and converts them into corresponding angular or linear displacements. It is a complete digital Executor for schema conversion. So what can stepper motors be used for? Let's find it out from the below.

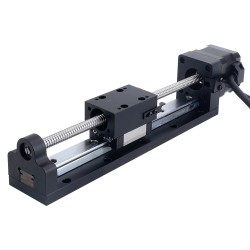

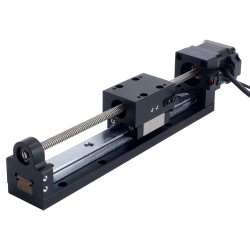

First let's briefly understand how it works. The working principle of a stepper motor is a motor that converts a pulse signal into a linear displacement or an angular displacement. Every time an electric pulse comes, the stepper motor rotates an angle, driving the machine to move a short distance. The stepper motor can easily achieve the correct positioning operation, and can control the correct rotation angle and speed through the pulse signal, so it is usually used in various non-standard equipment and automatic machinery, such as CNC machine tools, medical equipment, textile printing, packaging machinery , electronic equipment, robots, etc. What's more, stepper motor products are also widely used in robots, intelligent automation, industrial equipment, CNC machine tools, medical equipment, textile printing, engraving machines, laser marking machines, laser cutting machines, laser engraving machines, electronic equipment, stripping Line machines, packaging machinery, advertising equipment, labeling machines, constant speed applications and many other industries equipment. Apart from the above, stepper motors are used in most industrial equipment industries as well .For example, the nucleic acid detection machines and mask-making equipment used during the spread of the new crown epidemic all use two-phase stepping motors to make them.Besides, Most stepper motors like those used in computerised embroidery machines are three-phase hybrid stepper motors, and the use of subdivision drive technology can greatly improve the running quality of stepper motors, reduce torque fluctuations, suppress oscillations, reduce noise and improve step resolution. In addition, the stepper motor is a displacement motor, so it is mainly used in some occasions with positioning requirements, such as: wire cutting table dragging, tufting machine table (pore positioning), packaging machine (fixed length). Stepper motors are used in almost all situations involving positioning. Because the stepper motor is used to convert the corresponding angular displacement, it is widely used in ATM machines, inkjet printers, cutting plotters, photo machines, spraying equipment, medical instruments and equipment, computer peripherals and mass storage equipment, precision instruments, industrial control system, office automation, robotics and other fields.Stepper motors are especially suitable for applications that require smooth operation, low noise, fast response, long life, and high output torque.More, stepper motors are widely used in computer embroidery machines and other textile machinery and equipment. This type of stepper motor is characterized by low holding torque, fast response to frequent starts, low running noise, stable operation, good control performance, and complete machine low cost.Hope the above content can help you better understand the application of stepper motor. Thanks for reading.