The Functions of Digital Stepper Driver

The digital stepper driver is an executing mechanism that can convert the electrical pulse signal it is subjected to into angular displacement. When it receives an electronic pulse signal, it will rotate by a fixed angular displacement in a direction set previously.We can control the angular displacement by controlling the number of pulses it sends, so as to achieve the purpose of accurate positioning. By the control of the frequency of its pulse signal, the speed and accelerated speed of the motor can be controlled, so as to achieve the purpose of speed adjustment and positioning.It is widely used in a variety of large and medium-sized numerical control devices with high resolution, such as carving machines, crystal grinders, medium-sized numerical control machines, electroencephalographic embroidery machines, packaging machines, springs, dispensers, cutting and feeding systems, etc.

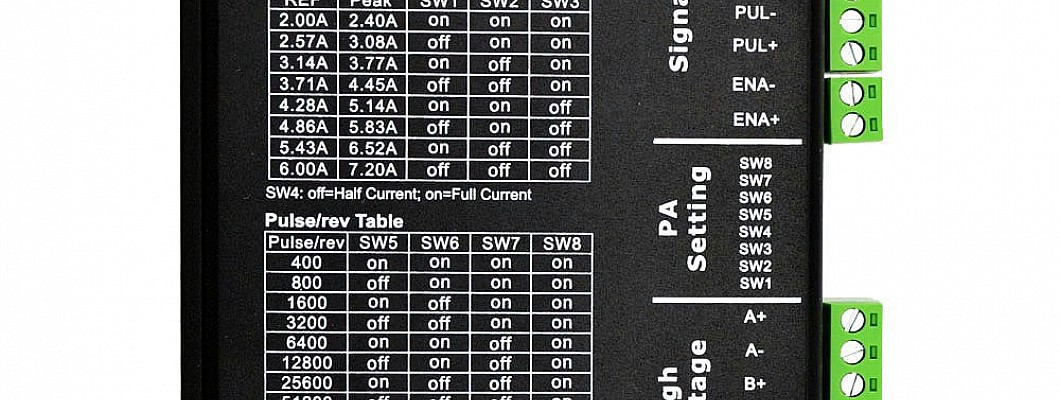

The phase of a stepping motor refers to the number of coil groups inside the stepping motor. General speaking, there are two-phase motors, three-phase motors, four-phase motors and five-phase motors. The different phases will result in a different step angle.The step angle of a common two-phase step motor is 1.8 degrees, three-phase is 1.2 degrees, and five-phase is 0.72 degrees. Not equipped with a subdivision driver, the user mainly relies on selecting different phases of the stepping motor to satisfy the request of the step angle. If a subdivision drive is used, the phases will become no use in that the use can directly change the step angle on the drive.

The subdivision of the stepping motor driver will result in a qualitative leap in the motor's performance, but all of this is generated by the driver itself and is independent of the motor and control system. When in operation, the only thing that users need pay attention to is the change of the step angle, which exerts an influence on the frequency of the signal sent by control system. Since the step angle of the stepping motor will become smaller after subdivision, the frequency of the step signal should be improved accordingly. Taking the 1.8 degree of the stepping motor as an example, the angle is 0.9 degrees when it is in half-step state, and 0.18 degrees when it is in ten-segment state. On the condition that the motor rotate at the same speed, the frequency of the step signal sent by the control system is 5 times of that in ten-segment state.

The accuracy of ordinary stepping motor is 3~5% of the step angle. The single-step deviation of the stepping motor does not affect the accuracy of the next step, so the accuracy of the stepping motor is not accumulated.