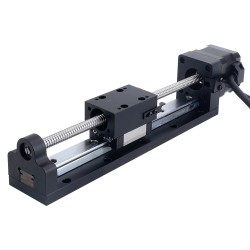

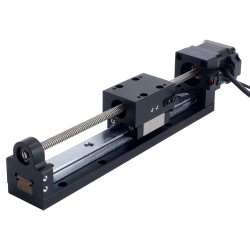

What is a ball screw?

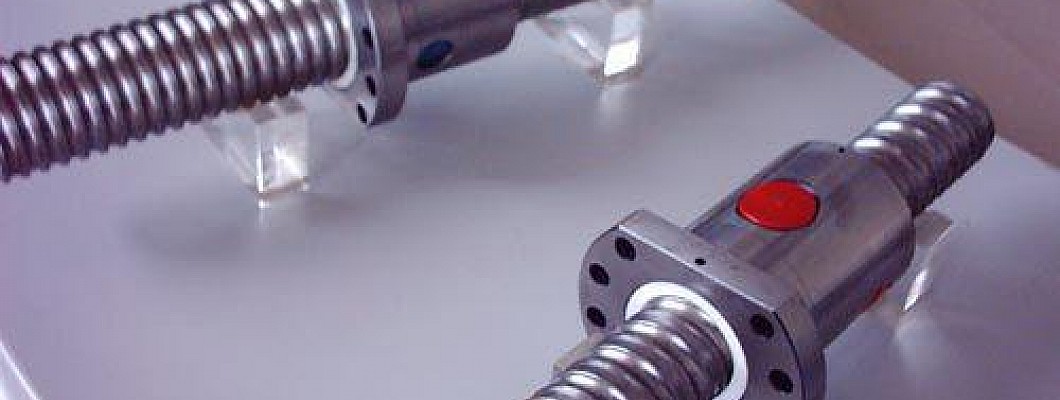

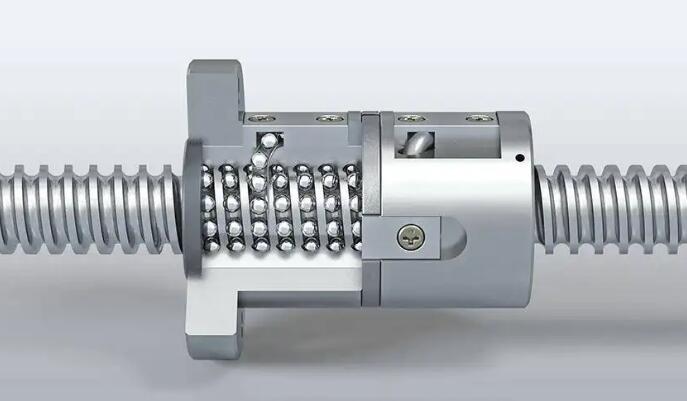

The ball screw consists of a screw and nut with matching grooves and ball bearings that move between them. Its function is to convert rotary motion into linear motion or convert linear motion into rotary motion. Ball screw is the most commonly used transmission element in tool machinery and precision machinery, and has the characteristics of high precision, reversibility and high efficiency. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

The difference between ball screw and lead screw

The basic difference between a lead screw and a ball screw is that a ball screw uses a ball bearing to eliminate friction between the nut and the lead screw, whereas a lead screw does not.

1. Different structure

There are balls in the ball screw, and an arc profile on the screw shaft. This profile is hovering on the shaft according to a certain lift angle (lead angle). The ball is designed in the nut and rolls in the arc profile of the screw shaft, so it is rolling friction.

There are no balls in the trapezoidal screw, so the movement between the nut and the screw shaft completely relies on mechanical contact to produce sliding, which is sliding friction.

2. Different transmission efficiency

The coefficient of friction of rolling friction is much lower than that of sliding friction.

For example, both NSK and THK show that ball screw has a coefficient of friction between 0.003 and 0.01, while lead screw only has a coefficient of friction between 0.1 and 0.2.

As another example, REXROTH shows that the coefficient of friction of ball screws is between 0.005 and 0.01, while the coefficient of friction of lead screws is between 0.2 and 0.3.This is why the transmission efficiency of most ball screws is as high as 90%, and some even reach more than 95%, while the transmission efficiency of most lead screws is less than 70%.

The transmission efficiency of the trapezoidal lead screw is low. From the perspective of energy, it is because of sliding friction, especially high-speed motion, which generates a lot of heat. If the lead screw or nut can't stand it, it will "burn". The lead screw is not suitable for high-speed operation requirements, and its maximum speed generally does not exceed 3000RPM.

The ball screw, because of rolling friction, does not generate so much heat, and the speed can reach very high, such as 10000RPM.

3. Different self-locking

The theory shows that when the lead screw transmission efficiency is greater than 50%, there is no self-locking, and when the transmission efficiency is less than 35%, there is self-locking. Therefore, the ball screw has no self-locking property, while the trapezoidal screw has a certain self-locking property.

As far as the Z direction application is concerned, the lead screw has the advantage of self-locking. Of course, in the actual situation, factors such as accuracy and speed also need to be considered.

4. Different manufacturing materials

The ball screw shaft is generally made of stainless steel or alloy steel, and the nut is generally made of copper, because copper can bear a large load, and at the same time, the friction coefficient is small, and it has a certain self-lubricating effect, just like some of our common linear bearings, or planes Skateboards, which also use copper, are exactly that reason.

The trapezoidal lead screw shaft is also made of stainless steel or alloy steel. For nuts, it is a little different from ball screws. In many cases, lead screw nuts use non-metallic materials. For example, when the load is low, synthetic engineering materials with low friction coefficient and high temperature resistance are generally used, such as nylon, race steel, PEEK, VESPEL, PET, PPS and other materials, mixed with Teflon (PTFE), to achieve low friction coefficient, At the same time, it has certain heat resistance.

5. Different applicable scenarios

The lead screw has sliding friction, and excessive speed will generate high heat on the joint surface, resulting in increased wear. Therefore, the lead screw is suitable for applications with light weight and low speed requirements. At the same time, the lead screw, because of its lower precision, is often more suitable for applications that do not require high precision, such as slow transfer, handling, etc. Ball screws, on the other hand, have low heat generation and high precision, and are generally more suitable for applications that require smooth motion, high efficiency, high precision, and long-term continuous or high-speed motion, such as semiconductor equipment.

6. Working life

Normally surface friction force of the rolling friction of the ball is small. Under the premise of various cleaning and maintenance operations, working life of the ball screw is longer than that of the trapezoidal screw.