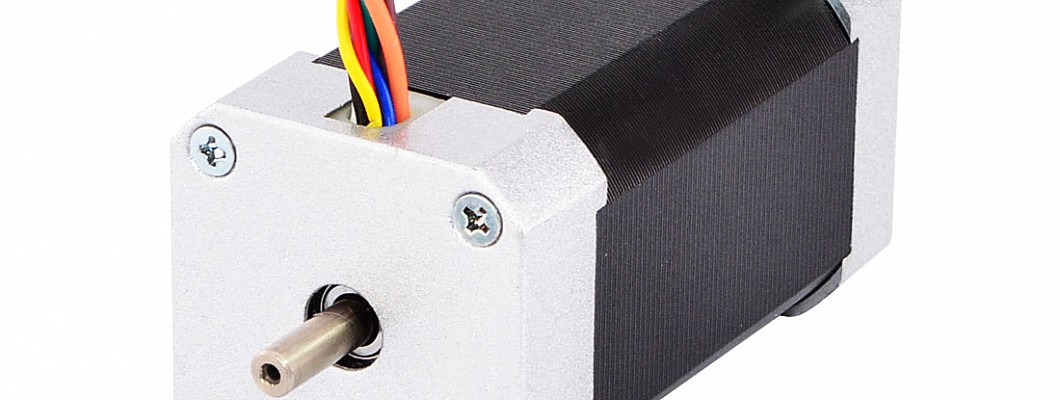

The wide use of DC gear motors is well known to all. It can be divided into brush motor, brushless motor, and other types in accordance with diverse uses and requirements. The former two kinds of motors are considerably prevailing devices which we may use.

Then what on earth the differences between these two motors? We can mainly account for them from the following three aspects:

1. Scope of Application

DC brushless gear motors are often applied to those devices requiring accurate control and fast rotation, such as aero-model motor and precise instruments which demand high speed of rotation. While brush gear motors are widely used in power equipment, including factory motors, domestic smoke extractors, etc. Even though series motor is able to rotate at high speed, it’s lifetime cannot be as ideal as brushless motor due to its easily worn-out carbon brush.

2. Life Span

Generally, the DC brushless gear motor can be used as long as several thousands of hours. Of course, a high-quality bearing contributes to a longer life span. However, it is necessary to change carbon brush when brush motor works longer than several hundreds of hours. Otherwise, it would have easily caused damage to bearing and the motor.

3. Efficiency

Remarkably controlled by digital variable frequency, the brushless motor is easy to achieve a few rpm to ten thousand rpm. While brush motor begins with a relatively constant speed, so it’s a little difficult for it to adjust speed. What’s about series motor? Its short life span cannot be ignored, though it also can reach 20000 rpm.

Considering concrete application fields, various requirements and respective advantages, we need make a correct decision to choose whether brush gear motor or brushless deceleration.