17 Jul

The answer is yes, the stepper motor must use a driver to work properly. So why does a stepper motor need a stepper motor driver?

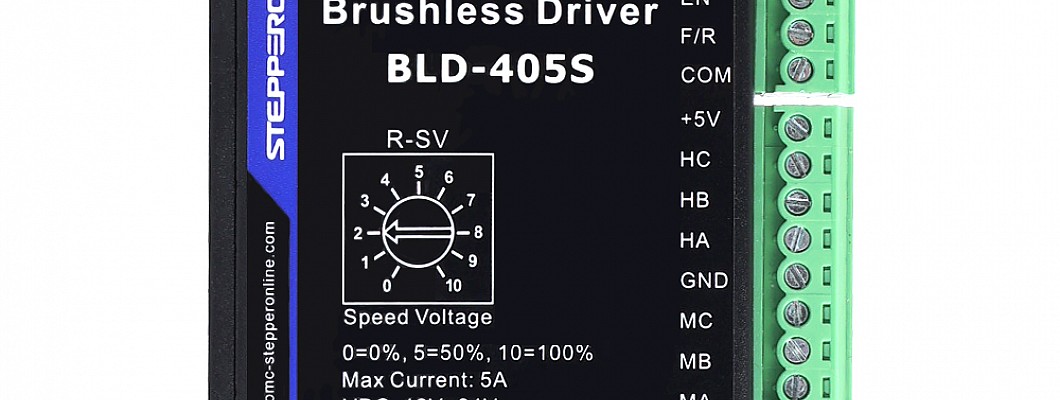

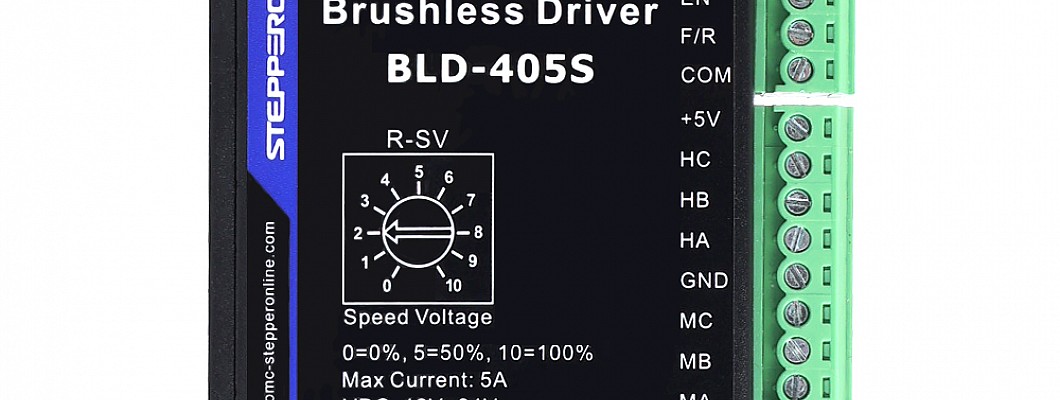

The first reason is that the motor needs the driver to adjust the voltage and current: First of all, let us first understand the working principle and control of stepper motors. The basic working principle of a stepper motor is: energize one or more stator phases, the current passing through the coil will generate a magnetic field, and the rotor will align with this magnetic field; apply voltage to different phases in sequence, and the rotor will rotate by a specific angle and finally reach the desired location. The control of a stepper motor is: the motor coils need to be energized in a specific sequence to create the magnetic field that the rotor will align with. There are several devices that can provide the necessary voltage to the coils to run the motor properly (start with the one that is closer to the motor). Transistor Bridge: A device that physically controls the electrical connection of the motor coils. The transistor can be thought of as an electronically controlled circuit breaker, the coil is connected to the power supply when it is closed, and the current flows through the coil. Each motor phase requires a transistor bridge. Pre-driver: A device that controls the activation of transistors, which is controlled by the MCU to provide the required voltage and current. MCU: A microcontroller unit, usually programmed and controlled by the motor user, that generates specific signals for the pre-driver to obtain the desired motor behavior. It follows that the correct voltage and current are critical to the motor operation, and so is the microcontroller, but many stepper motors operate at voltages higher than the microcontroller's operating voltage limits. In addition, stepper motors require more current than a microcontroller or a microprocessor can handle. If you want to control a stepper motor using a micro-controller, you have to deal with voltage and current first. This is why a driver is used, because an important feature of a stepper motor driver is that it controls the voltage across the winding and the current flowing through the winding: With voltage control, the driver can regulate the voltage across the windings, resulting in torque and step speed that depend only on the motor and load characteristics. Current controlled drives are more advanced because they can regulate the current flowing through the active coil, giving better control over the torque produced and thus better control over the dynamic behavior of the overall system.Another reason is: the stepper motor needs a driver to control the speed

Stepper motors control the speed through electric pulses, but the frequency of electric pulses is not the only factor that affects the speed of stepper motors. The driver is the main component of controlling the stepper motor, you can achieve more precise control by adjusting the parameters of the driver. The specific principle is as follows: 1. Current control: The motor speed is proportional to the current, because the motor of the stepper motor needs to consume a certain amount of current to work normally, so the driver needs to control the speed of the stepper motor by controlling the current. 2. Speed loop control: The speed loop control in the driver can adjust the output pulse frequency according to the speed of the motor, so as to realize the control of the speed of the stepping motor. 3. Acceleration control: The acceleration control in the driver can set different accelerations according to the motion requirements, so as to achieve smoother and more precise motion effects.You can control the stepper motor speed by adjusting the driver parameters

The driver usually has several adjustable parameters. By adjusting these parameters, the control of the speed, acceleration, and deceleration of the stepping motor can be realized. These parameters include but are not limited to the following: 1. Stepping motor phase current Adjusting the phase current of the stepping motor can control the speed and torque of the stepping motor, and the specific value should be adjusted according to the motor and mechanical structure, working load and other actual conditions. 2. Number of subdivision steps The number of subdivision steps refers to subdividing each step pulse into several microsteps, which can control the rotation of the stepper motor with a higher resolution, thereby obtaining a finer motion effect. However, subdividing the number of steps reduces the maximum speed of the stepper motor. 3. Maximum Speed The maximum speed refers to the maximum rotation speed of the stepper motor, which can be adjusted by modifying the parameters in the driver. 4. Acceleration, deceleration Acceleration and deceleration are used to control the acceleration and deceleration when the stepping motor starts and stops. Adjusting these parameters can make the stepping motor move more smoothly. In addition to general-purpose drivers, in order to obtain higher control accuracy and motion stability, high-precision drivers can also be used for control. High-precision drives usually have the characteristics of higher subdivision steps, higher speed, and higher precision. However, high-precision drives are relatively expensive. Of course, there are many reasons why a stepper motor needs a driver. For example, the driver of a stepper motor can provide higher output power. The output power of the motor is related to its driver, and the driver can provide higher output power to meet the needs of the motor. Again, the driver of the stepper motor can provide accurate frequency control. Stepper motors can provide precise angle control, but without accurate frequency control, stepper motors cannot function properly. In short, a stepper motor must use a driver to work properly. The driver of the stepper motor can provide higher output power, more accurate output current voltage, frequency control, more precise position control, and higher efficiency. Therefore, the stepper motor must use a driver to work properly.