Stepper motors and servo motors are both important control components in industrial drive control and are used in a wide range of applications. However, for many customers they do not understand the main differences between these two types of motor, therefore they are never sure how to choose. So, what are the main differences between stepper motors and servo motors? The following is a brief description of their differences.

1.Principle of operation

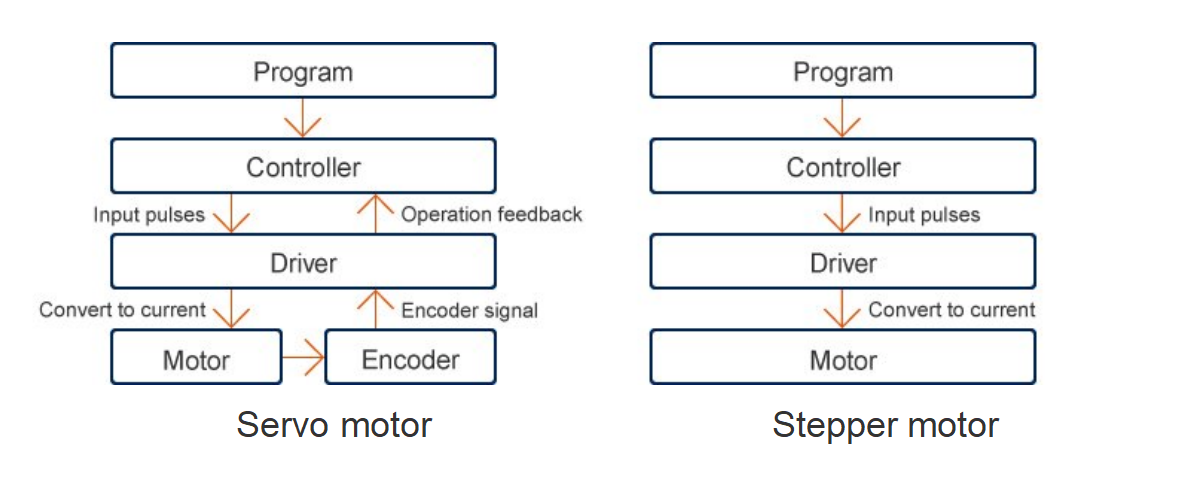

These two types of motors are very different in terms of working principle. Stepper motors are open-loop control elements that convert electrical pulse signals into angular or linear displacements.

As for the servo motor, it relies mainly on pulses for positioning. The servo motor itself has the function of sending out pulses. For every angle of rotation of the servo motor, a corresponding number of pulses will be sent out, thus forming a closed loop with the pulses received by the servo motor, so that the system will know exactly how many pulses have been sent and received back, which enables precise control of the rotation of the motor and accurate positioning.

2.Speed and Torque

Stepper motors are prone to low frequency vibration when running at low speeds, so when stepper motors are working at low speeds, damping technology is usually required to overcome the low frequency vibration phenomenon, such as adding dampers to the motor or using subdivision technology on the driver. Servo motors do not suffer from this phenomenon and their closed-loop control characteristics determine that they maintain excellent performance at high speeds. The moment-frequency characteristics of the two are different, and generally the rated speed of a servo motor is greater than that of a stepper motor. The output torque of the stepper motor will fall as the speed rises, while the servo motor is a constant torque output, so the stepper motor generally has no overload capability, but the AC servo motor has a higher overload capability.

In summary:

Speed and torque of stepper motor:

- a. Stepper motor has less speed than servo motor, the normal stepper motor has a maximum speed of 1500 RPM.

- b. As Motor speed increases motor torque reduces.

- c. It gives excellent torque in low-speed applications.

- d. Stepper Motor is not useful in the torque control applications.

Speed and torque of servo motor:

- a.Servo motor has a higher speed than a stepper motor, however, in the market, you will get different speed drive up to 5000 RPM.

- b.We get high torque at a higher speed.

- c.It gives excellent torque in high-speed applications.

- d.Servo Motor can be used in the torque control applications. (Ex. Nut tighten tool)

3.Operational performance

Stepper motors are generally open-loop controlled. Loss of steps or blocking can occur at too high a starting frequency or under too large a load. When using them you need to take care of speed issues or add encoders for closed loop control. While the servo motor is a closed-loop control, it is easier to control and does not suffer from lost steps.

4.Cost

The stepper motor has an advantage in terms of cost performance. To achieve the same function, the price of a servo motor is higher than that of a stepper motor of the same power. The high response, high speed and high accuracy of servo motors inevitably means that they are more expensive.

5.Select the most suitable motor

It is generally considered that servo control systems perform better in applications requiring speeds in excess of 800 RPM and where high dynamic response is required. Stepper motors are more suitable for applications requiring lower speeds, low to medium acceleration and higher holding torque.

Actually, both servo motors and stepper motors have their own characteristics and there is a possibility of interpenetration in their applications. With advances in precision manufacturing and drive control technology, stepper technology is also being improved and stepper motors still maintain an important industry position.

Blew are some tips when you choose servo motor or stepper motor?

A.Select the servo motor, if your requirement as per below,

- a.If you want position feedback.

- b.For high-speed applications.

- c.Speed control applications.

- d.Torque control applications.

- e.For complex machinery systems.

- f.For more precise and fast equipment.

B.Select the stepper motor, if your requirement as per below:

- a.Your application should not require position feedback.

- b.For low-speed applications.

- c.You can use stepper motor only in position control applications.

- d.For simple machine applications.

- e.If your application is for holding torque.

6.Industrial applications of servo and stepper motors

a.Typical application of servo motor:

- Robots

- Packaging machinery

- Camera auto-focus

- CNC machines

- Cutting machines

- Shearing and forming machines

- Proportional valve control

- Printing machinery

b.Typical application of stepper motor:

- Low cost CNC machines

- Ball screw movement (spray painting or paper cutting machines)

- Precise up/down movement (welding machine)

- 3D printers

- Small robots

- Textile machines

- Medical equipments

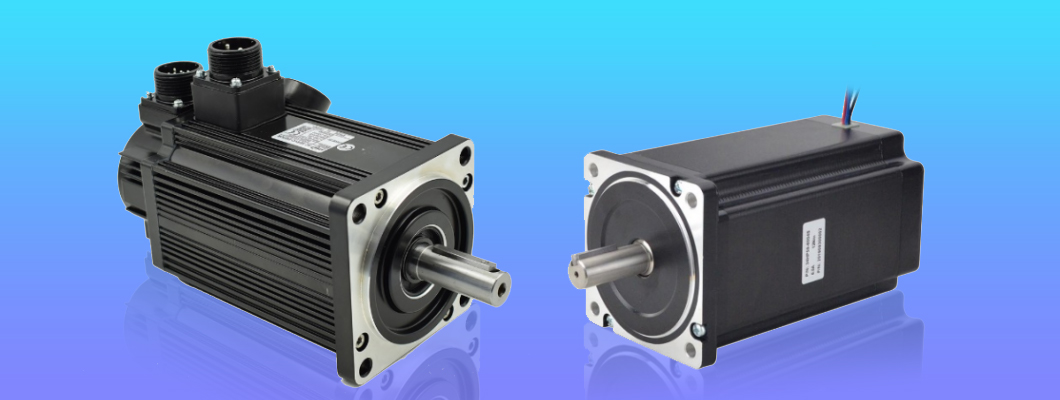

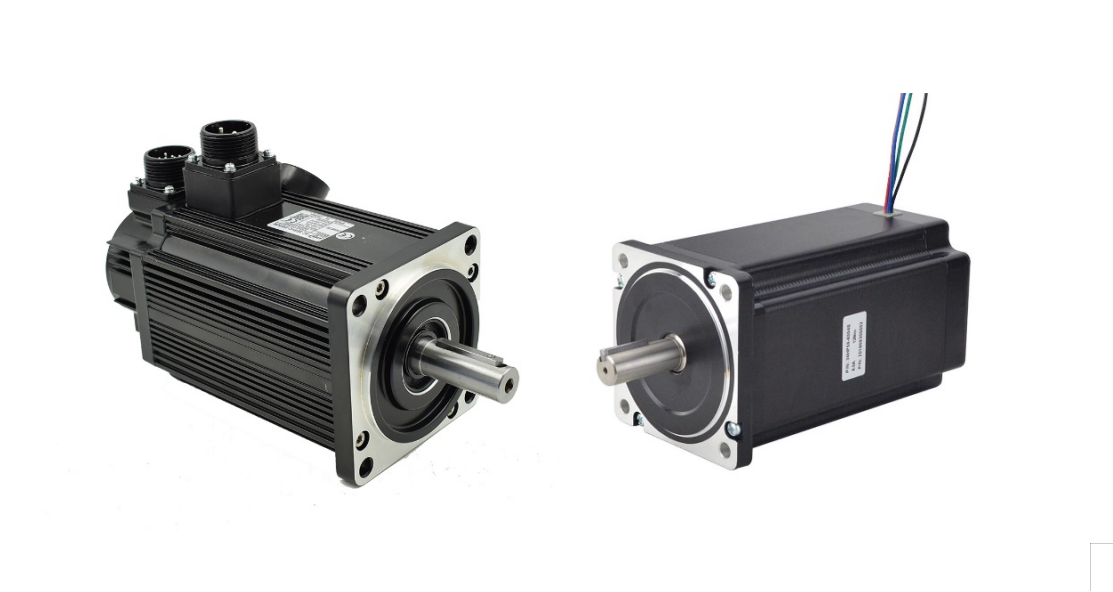

7.Servo Motor vs Stepper Motor(in table)

| # | Specifications | Servo Motor | Stepper Motor |

| 01 | System function | Closed-loop system (position feedback or encoder present) | Open-loop system (no position feedback or encoder) |

| 02 | Cost | Very expensive | Cost-effective |

| 03 | Speed | High Speed (5000 RPM maximum) | Low Speed (1500 RPM maximum) |

| 04 | Torque/ speed control odf | torque-control or speed-control mode | No torque-control or speed-control mode |

| 05 | Input voltage | AC current use | DC current use |

| 06 | Torque | High torque in high speed | High torque in low speed |

| 07 | Requirement | tuning required | No tuning required |

| 08 | Consuming power | Consumes more power | Consumes less power |

| 09 | Function | Complex for commissioning | Simple and easier for commissioning |

| 10 | Size | 50W to 15KW motor size available | Maximum 750W motor size available |

Currently, STEPPERONLINE provide a series of Integrated Easy Servo Motors. As our first-generation servo motor, it is significantly superior in terms of plug-and-play operation. In contrast to the standard type of servo motor, the integrated simple servo motor already has a built-in driver.

We will launch our next generation of AC Servo motor by the end of 2021.