What is a Servo Motor?

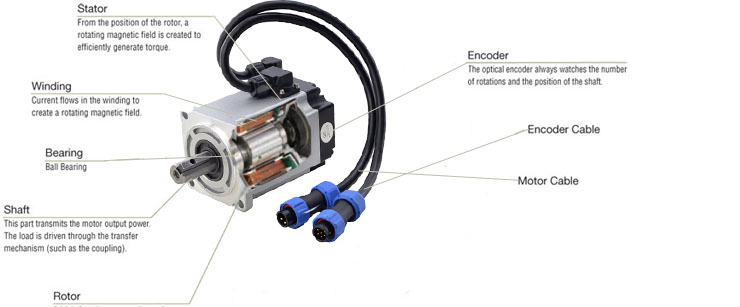

Servo motor is a common motor that absolutely obeys the command of the control signal. Before the control signal is sent, the rotor is stationary. Once the control signal is sent, the rotor rotates immediately and instantly stops when the control signal disappears. If the motor as a controlled device, associated with servomechanism is DC motor, then it is commonly known as a DC Servo Motor. If AC operates the controlled motor, it is known as a AC Servo Motor.

Servo motor is the implementation element in the automatic control system since its obvious feature is adjustment. When there is an adjustment data signal, the servo motor runs, and the speed is proportional to the adjustment voltage. After the adjustment data signal voltage is removed, the servo motor stops running immediately.

Servo Motor Applications

Servo motors have high running accuracy and output torque accuracy, and are mainly used in equipment that requires relatively high process accuracy, processing efficiency and work reliability, such as:1. Machinery industry: machining centers, CNC punching machines, bending machines, shearing machines, PLC program controllers, various types of automotive testing equipment, assembly equipment, and welding equipment.

2. Printing industry: drying machine, printing machine, offset printing machine, rotary machine, laser phototypesetting, proofing equipment, automatic punching machine, inkjet printer; folding machine, paper cutter, sewing machine, glue binding machine, automatic Corrugated cardboard (box) production line, automatic paper feeding and gluing machine, computer three-side bag sealing machine, shaftless high-speed offset printing machine, etc.

3. Medical industry: monitors, ultrasound machines, CT control boxes, electrocardiogram (EEG) testers, X-ray machines, slicers, hemodialysis machines, temperature controllers, etc.

4. Food industry: sterilizer, homogenizer, labeling machine, can making machine, flow controller, sealing machine, packaging machine, coffee machine, etc.

5. Rubber tire industry: steel belt production line, inner lining extrusion line, steel wire calender, double compound extruder, steel cord cutting machine, heavy internal mixer, radial tire wire machine, etc.

6. Elevator industry: door control and floor control of various elevators.