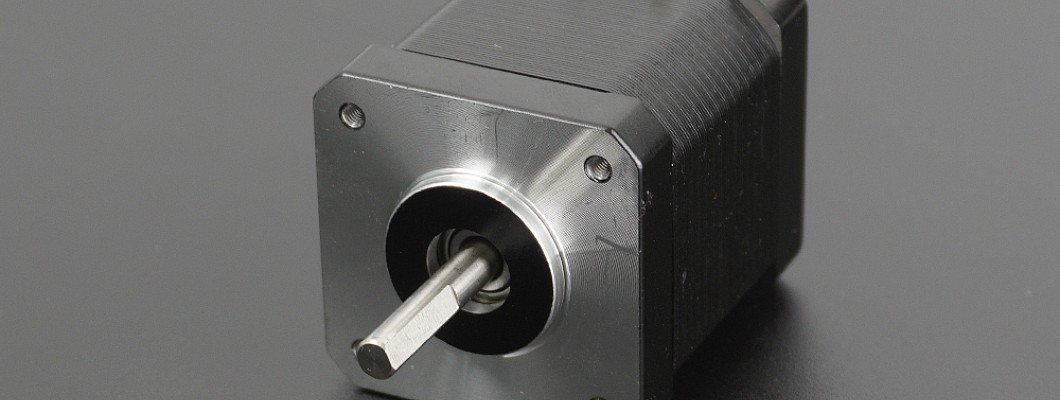

There may be multiple reasons for the vibration and noise generated by a stepper motor when operating at low speeds, including:

Due to the discrete movement of the rotor, the stepper motor produces significant mechanical vibration, leading to noise at low speeds. This is because the rotational speed of the motor is slow, and the torque waveform of the stepper motor generates significant pulsation, increasing mechanical vibration.

Electromagnetic cogging of the stepper motor can also generate vibration and noise. When the stepper motor operates, the electromagnetic iron core will continuously attract and release, causing vibration and noise in the rotating part.

The control accuracy of the stepper motor drive circuit can also affect the noise and vibration of the stepper motor. If the control accuracy of the drive circuit is not high enough, the motor will experience jitter, resulting in noise and vibration.

The structure and materials of the stepper motor can also affect noise and vibration. The materials and manufacturing precision of components such as the rotor, stator, and bracket of the stepper motor can all affect noise and vibration. Here are some common solutions: 1. Selecting a suitable driver: Choosing a suitable driver can effectively reduce the vibration and noise of the motor. Microstep drivers are recommended as they can divide the stepper of the stepper motor into smaller microsteps, making the motor run more smoothly. 2. Increasing current: When the motor operates at low speeds, the current decreases, which can lead to increased vibration and noise. Increasing the current to improve the motor's torque and stability can effectively reduce vibration and noise. 3. Reducing load: A heavy load can also lead to increased vibration and noise of the motor. By reducing the load, the vibration and noise of the motor can be reduced. 4. Installing shock absorbers: Adding shock absorbers between the motor and external structure can effectively reduce the transmission of vibration and noise. 5. Checking the motor bearings and mechanical structure: Damage or poor design of the motor bearings and mechanical structure can also lead to increased vibration and noise of the motor. Checking and replacing damaged bearings and structures, or redesigning the mechanical structure, can effectively reduce vibration and noise. 6. Using low-noise materials: Choosing low-noise materials when manufacturing the motor and mechanical structure can also effectively reduce vibration and noise. For example, using rubber materials can reduce vibration and noise transmitted to the external structure. In conclusion, there are many ways to reduce motor vibration and noise. It is necessary to consider various solutions according to the actual situation and select the appropriate one.