Choosing the right motor for a CNC mill, lathe or router depends on several factors, including the requirements of the project and the characteristics of the motor. Here are some important factors to consider when choosing a motor for a CNC machine:

Power requirements: The power required by the motor depends on the size and weight of the machine, the type of material being worked on, and the cutting speed required. Generally, a larger motor will be needed for heavier and tougher materials.

Speed range: The motor should be capable of operating at different speeds to handle different cutting requirements. The speed range of the motor should be matched to the capabilities of the machine.

Torque requirements: The torque requirement depends on the type of material being cut, the depth of cut, and the speed of the machine. A motor with higher torque will be needed for tougher materials or deeper cuts.

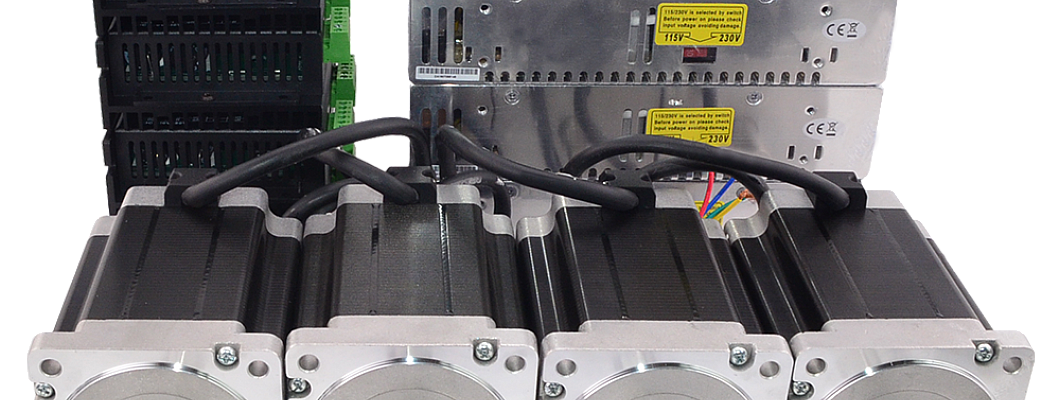

Type of motor: There are various types of motors available, such as stepper motors, servo motors, and DC motors. Each type of motor has its own advantages and disadvantages, and the choice will depend on the specific requirements of the project.

Control system: The motor should be compatible with the control system of the CNC machine. The control system can determine the type of motor that is required, as well as the type of driver and power supply that will be needed.

Budget: The cost of the motor will depend on its power, speed, torque, and type. It is important to balance the requirements of the project with the available budget.

Overall, the choice of motor for a CNC mill, lathe, or router depends on the specific requirements of the project, as well as the characteristics of the machine and the control system. It is important to carefully consider all of these factors before making a decision.