What is a servo motor?

Definition of a servo motor

The term "servo" refers to the control mechanism and comes from "servus", the Latin word for slave. Servo motors are named after the fact that they can be relied upon to operate "exactly as directed".

A motor that can control parameters such as position and speed is referred to as a servo motor, irrespective of how this control is achieved. Consequently, the term is sometimes used to include stepper motors and coreless motors.

Within the context of our intentions here, however, a servo motor will be defined as a motor with an encoder (rotational motion detector) along with a driver that uses information from that encoder to control speed and position (angle of rotation).

Differences between servo motors and stepper motors

Like servo motors, stepper motors are able to control their rotation angle in response to external inputs. They can therefore also be used for positioning machinery and similar applications. But there are many differences between these two types of motor.

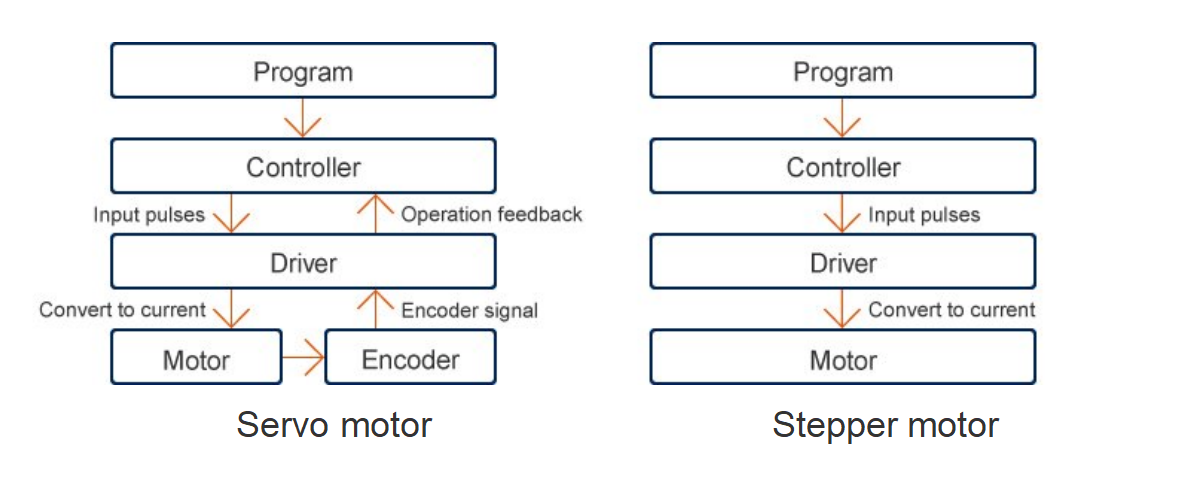

1. Control mechanism

Servo motors have an encoder (rotational motion detector) which locates their rotational position and provides feedback control of the motor position. In this way a precise stopping accuracy is provided and the motor is able to return to its original position in the event of a deviation from the motor position at the time of stopping. In contrast, for stepper motors, the angle of rotation of the motor is in proportion to the number of input pulses. Therefore, it controls the position by the number of input pulses received from the controller. Though the need for a position sensor is avoided, it also means an absence of means to detect position deviations. For example, unexpected changes in load can cause the motor to become desynchronized (meaning that the motor rotates at a different angle to that specified by the input).

2. Torque and speed

Servo motors can operate at high speeds and can also provide reliable torque over a wide speed range from low to high. Stepper motors can provide high torque at low speeds, but their torque decreases as speed increases, making them less suitable for high-speed operation.

3. Cost

As servo motors require a rotary encoder and servo controller (driver) they are more expensive than stepper motors.

To read more details about servo motor and stepper motor, please click: Servo Motor vs Stepper Motor.

History of servo motors

Beginning in the 1950s, the interest in factory automation began to grow in the United States, initially in areas such as belt conveyors, automatic machinery and industrial robots. Early automated machinery and industrial robots inclined to use hydraulic or pneumatic techniques to control the positioning of actuators, but they suffered from problems in terms of accuracy, operational reliability, associated piping, hydraulic oil or air leakage.

Subsequently, with improvements in technology, the use of DC servo motors increased during the 1950s and 1960s and they began to be installed in industrial robots to replace troublesome hydraulic and pneumatic mechanisms.

Along with the advances in industrial robots came great technological advances in servo motors. AC servo motors became available in the 1980s. Their practical benefits include making the robots smaller and lighter and, as a result, servo motors are widely used in modern industrial machinery.

Types of servo motors

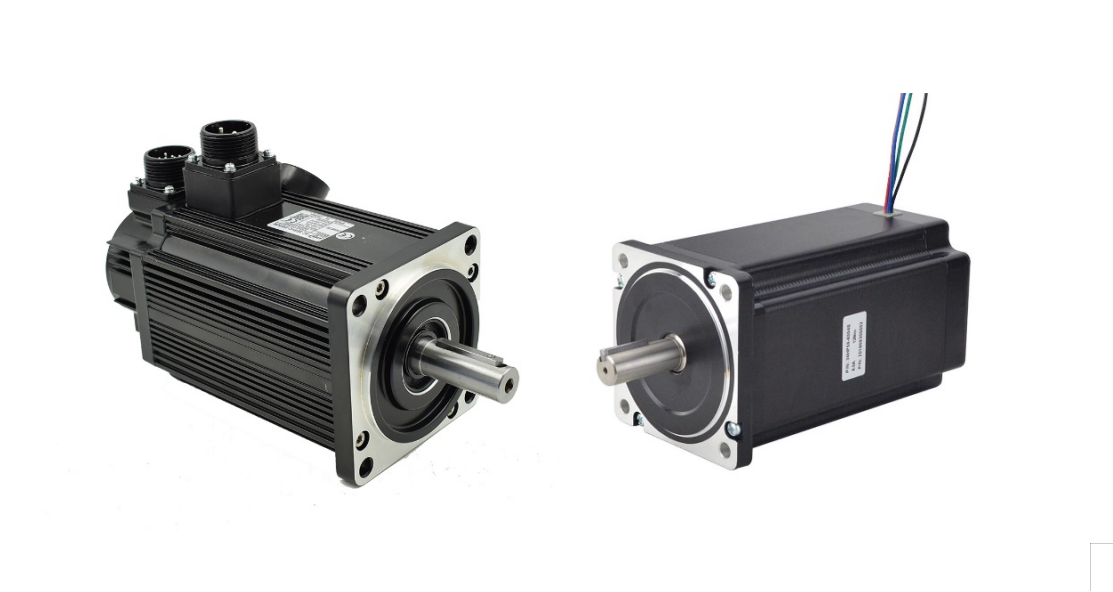

Servo motors can be divided into DC servo motors and AC servo motors.

1. DC servo motors

These are servo motors driven by brushed DC (direct current) motors. DC motors are easier to control than AC motors. They are widely used because of their small size and low cost, but the use of DC motors has been decreasing recently due to advances in AC motor control technology.

2. AC servo motors

These are servo motors driven by alternating current (AC) motors. Although more complicated to control than DC motors, advances in control technology have made them now the most common type of servo motor.

Depending on their drive mechanism, AC servo motors can be divided into synchronous motors (SMs) and induction motors (IMs). They are distinguished on the basis of their presence or absence of a permanent magnet.

SMs contain a permanent magnet. In order to increase the output of the motor, the use of permanent magnets needs to increase, permanent magnets are expensive and the cost of the motor becomes high. For this reason, they are widely used in low power applications (up to 10kW). However, with the availability of high-performance permanent magnets in recent years, synchronous AC servo motors are now the preferred default choice.

IMs do not use permanent magnets and tend to be used for higher output applications (10kW or more).

Servo motor applications

With their accurate positioning characteristics, servo motors are widely used in applications such as industrial robots and precision machinery. Examples of applications include the following:

- Industrial robot joints

- Humanoid robot joints

- Equipment control in food processing machines

- Equipment control in packaging machines

- Belt drives in conveyor systems

- Automatic doors in trains

- X-Y tables used in LCD and semiconductor inspection machines

- Presses/roll feeders

- Rotating stages for machine tools or inspection systems

- Control of presses

- Control of bonding machines

- Control of plastic molding machines

- Control of amusement machines

- Radio control and other hobby applications

- Coating or vapor deposition machines

- Spin cleaning machines for LCDs and semiconductors