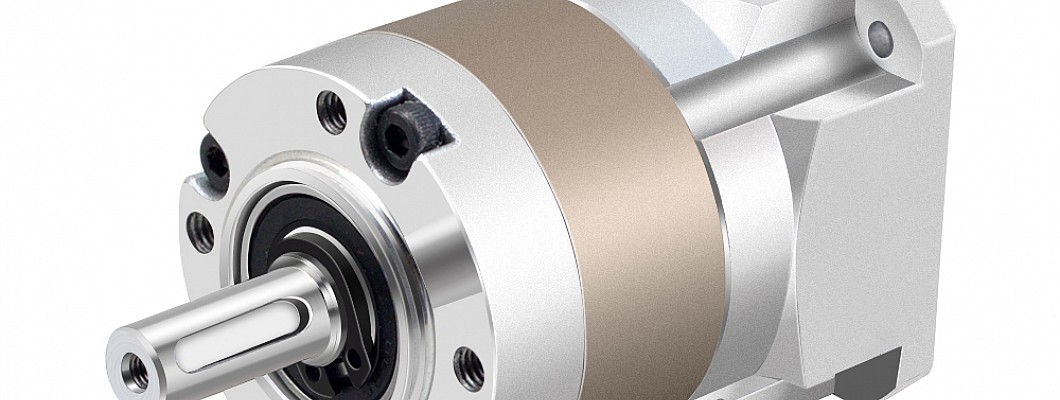

There are several ways to connect a planetary gearbox and a motor. Here are some possible methods:

1. Flange connection: A flange connector can be used to connect the planetary gearbox and motor. Flanges are typically circular metal components that are bolted or screwed onto the end faces of the motor and gearbox. This connection method is usually strong and reliable, and is suitable for larger machines.

2. Direct connection: The output shaft of the planetary gearbox and the input shaft of the motor can be connected directly together, typically requiring some additional components to ensure the connection is secure and precise. This connection method is relatively simple and suitable for smaller machines.

3. Coupling connection: A coupling is a component used to connect the motor and planetary gearbox, and can compensate for problems such as axial deviation, angle deviation, and torque shock. This connection method is suitable for machines that require high precision and reliability.

4. Gear connection: A gear connector can be used to connect the planetary gearbox and motor, which is suitable for machines that require large reduction ratios and high torque output.

5. Choosing the right connection method: Depending on the specific application and equipment requirements, select the appropriate connection method, such as flange connection, bearing connection, or tapered sleeve connection.

When connecting a planetary gearbox and motor, the following considerations should also be taken into account:

1. Determining the correct reduction ratio: The reduction ratio of the planetary gearbox is usually fixed, and the appropriate reduction ratio should be selected based on the application requirements. The larger the reduction ratio, the lower the output speed and the greater the output torque.

2. Selecting the correct motor: Select a suitable motor based on the rated torque and reduction ratio of the planetary gearbox. The rated output power of the motor should be greater than the power required by the actual load.

3. Ensuring proper alignment: During the connection process, it is important to ensure that the axes of the planetary gearbox and motor are aligned. Misalignment can cause unstable operation, noise, and vibration.

4. Ensuring proper lubrication: The planetary gearbox and motor require lubrication during operation. The type of lubricating oil and its usage should be selected and used according to the specific equipment requirements.

5. Regular inspection and maintenance: After the connection is completed, the operating status of the planetary gearbox and motor should be regularly checked, and necessary maintenance and care should be carried out to ensure normal operation and longevity of the equipment.

In summary, connecting a planetary gearbox and motor requires attention to the correct connection method, reduction ratio, motor selection, alignment, lubrication, and regular inspection and maintenance. Adherence to these considerations can ensure normal operation and long equipment life.