A stepper motor is an electromechanical device converting electrical energy into mechanical power. At the same time, a stepper motor is a brushless, synchronous motor that can divide a full rotation into a huge number of steps. When a stepper motor is applied with electrical command pulses in the proper sequence, the shaft or spindle of the stepper motor rotates in discrete steps, allowing precise control of the motor's position without any feedback mechanism, as long as the motor is sized for the application.

1. Construction of stepper motors

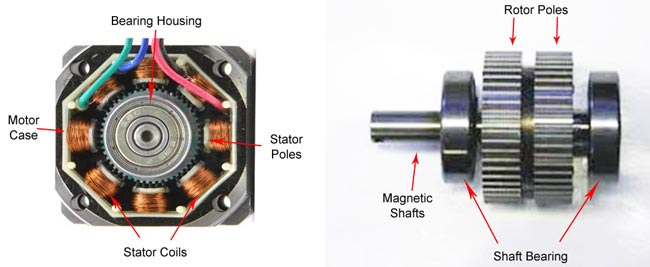

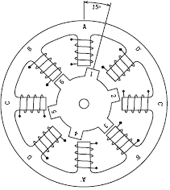

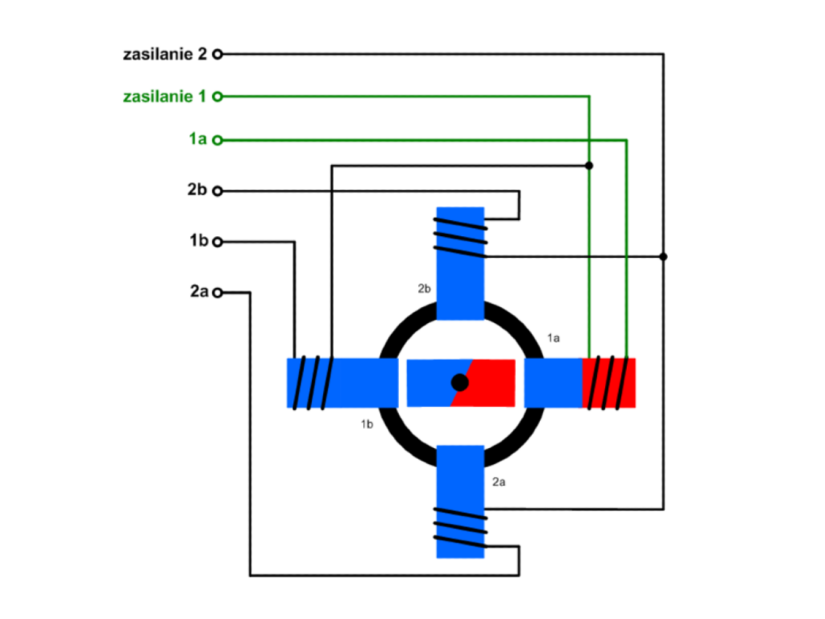

Stepper motors generally consist of front and rear end caps, bearings, center shaft, rotor core, stator core, stator assembly, corrugated washers, screws, and other parts. The two main parts of a stepper motor are the stator and the rotor. They are both composed of magnetic materials with six and four magnetic poles on them respectively. The six magnetic poles of the stator have control windings on them, and the two opposite poles form a phase.

2. Types of Stepper Motors

There are three basic types of stepper motors, reactive rotor: variable reluctance stepper motor(VR), active rotor: permanent magnet stepper motor(PM), combination of VR and PM: Hybrid stepper motor (HY)

Variable reluctance stepper motors

Variable reluctance stepper motors are the simplest type of stepper and are made up of a soft iron multi-tooth rotor and a wound stator. Both poles are magnetized when DC current is applied to the stator winding.

When the rotor teeth are attracted to the energized stator poles, rotation occurs. As the magnets of variable reluctance stepper motors are smaller and lighter than those of permanent magnet stepper motors, they are faster. The smaller the area between the rotor and stator gears of a variable-resistance stepper motor, the smaller the loss of magnetic force.

For this type of stepper motor, although the structure is simple and easy to control, the resolution is low and the torque is small.

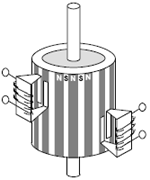

Permanent magnet stepper motors

Permanent magnets are incorporated into the motor structure of the permanent magnet stepper. The rotor position change will be caused by a change in the current direction in the coils, changing the magnetic poles. The rotor will rotate 90° as the direction of the current is properly changed. This single step of the motor, although useful in some applications, would be very large and inaccurate. Therefore, the really existing permanent magnet motors have more rotor poles and several magnets mounted on the rotor to increase the number of steps and positioning precision.

The magnetized rotor poles provide greater magnetic flux intensity and, as a result, permanent magnet motors exhibit better torque characteristics than variable reluctance stepper motors. The simple construction results in a moderately priced motor with fairly low resolution.

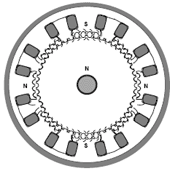

Hybrid stepper motors

Hybrid stepper motors are one of the most widely used types of stepper motors in the industry. Hybrid stepper motors combine the best features of variable reluctance and permanent magnet stepper motors, so they are more expensive. Hybrid stepper motors offer better performance in terms of step resolution, torque and speed.

The rotor of a hybrid stepper motor consists of permanent magnets, but unlike the models discussed above, the magnets are not mounted radially but magnetized axially. Normally, the rotor consists of two opposing magnetized rings placed on the motor shaft. It has slotted grooves in each ring to form rotor teeth.

The number of full steps per revolution can be calculated from the following formula:

- SPR = NR x Ø

- Where: SPR = number of steps per revolution

- NR = total number of rotor teeth (total for both yokes)

- Ø = number of motor phases

- or: NR = SPR/Ø

| Comparisons | Variable reluctance stepper motor(VR) | Permanent magnet stepper motor (PM) | Hybrid stepper motor(HB) |

| Cost | Medium | Relatively cheap | Relatively expensive |

| Design Structure | Simple | Medium | Relatively complex |

| Resolution | Step angle: 1.8°, 0.9° or less | Step angle: 3°~30° | Step angle: 1.8°, 0.9° or less |

| Torque speed curve | No significant torque drop at high speed | Large torque at low speed, significant torque drop at high speed | Large torque at low speed, significant torque drop at high speed |

| Noise | More noise | Less noise | More noise (better with microstep subdivision) |

| Heat generation | High temperature rise (need heat sink) | Low temperature rise | Low temperature rise |

| Microstep subdivision | Usually operate in full step only | Ferrite or neodymium-iron-boron magnets | Neodymium-iron-boron magnets |

| Rotor material | Silicon steel sheet (no permanent magnets) | Full step, half step, micro step | Full step, half step, micro step |

| Rotor surface | Multi-tooth structure on the rotor outer surface | Smooth and toothless | Multi-tooth structure on the rotor outer surface |

| Magnetic torque | Generates only attractive torque | Both attractive and repulsive torque during operation | Both attractive and repulsive torque during operation |

3. Types of Wiring

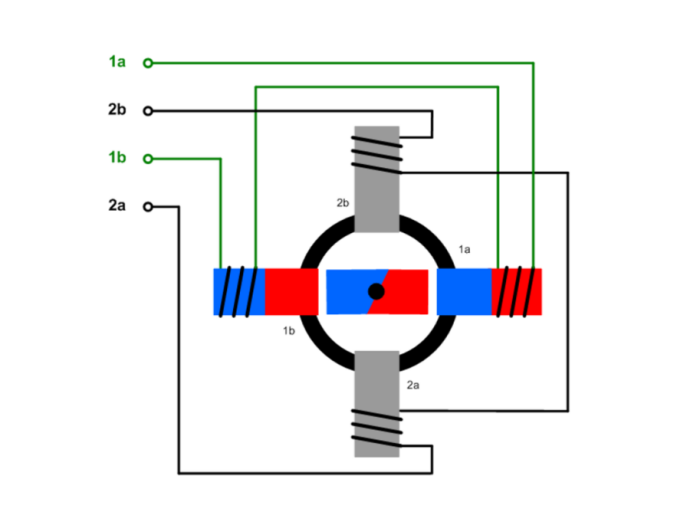

Another classification of stepper motors is based on the type of winding of the two-phase motor. Stepper motors are classified into unipolar and bipolar motors based on this classification.

The main difference is that unipolar motors operate with one current (voltage) polarity, while bipolar motors operate with two polarities, which means that the direction of current flow in the coils is variable. A further difference is that the motor coils must be connected in order to transfer power from the end of one coil to the beginning of the other. This connection method permits one polarity of current (voltage) to be used. A bipolar motor has a higher torque than a unipolar motor, but it is also more complicated to control it.

Bipolar stepper motor and the connection of its windings

Unipolar stepper motor and the connection of its windings

| Bipolar stepper motor | Unipolar stepper motor |

| Higher torque | Lower torque |

| Higher anchorage due to windings | Lower anchorage |

| Smaller | Larger |

| Cheaper | More expensive |

| More complicated control, which requires a board that includes power and slew control stages | Easier control by requiring only one power circuit to be completed |

4. Advantages of stepper motors

- Positioning - Due to stepper motors moving in precise repeatable steps, they perform well in applications that require precise positioning.

- Speed control - Precise motion increments provide excellent control of speed.

- Low-speed torque - Stepper motors have high torque at low speeds.

5. Disadvantages of stepper motors

- Low efficiency - Compared to DC motors, they use more current. Therefore they tend to run hot.

- Limited high speed torque - The torque of the motor drops quickly as speed decreases

- No feedback - Feedback is not used to specify possible missed steps

- High levels of vibration and noise - At very high speeds, operation of this motor is not easy.

- Possible loss of synchronization - Caused by factors such as unexpected changes in load

- Small torque toward inertia ratio

- Require a drive circuit

6. What are stepper motors used for?

As such stepper motors are a good choice for applications that require low speed and high accuracy. Some of these everyday applications are listed below:

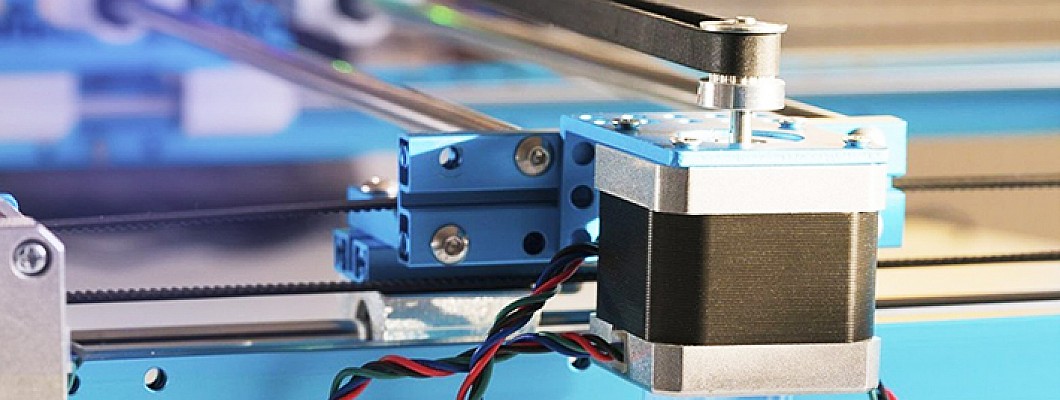

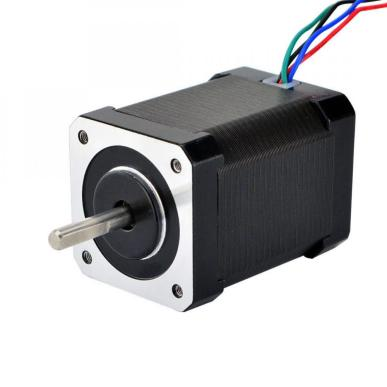

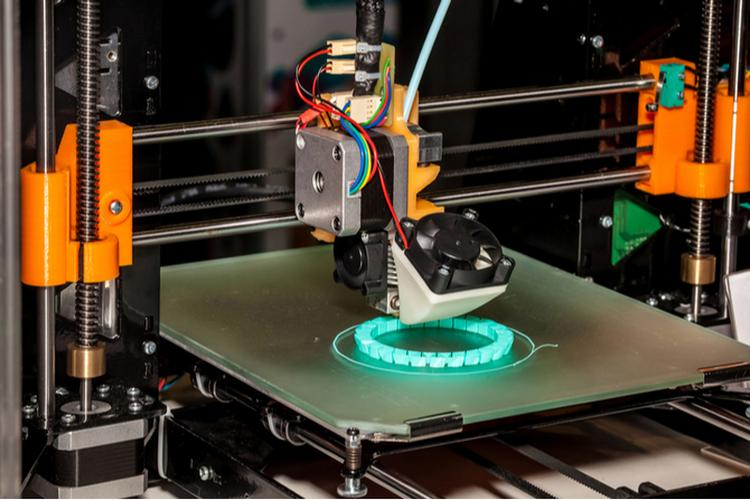

Stepper motors for 3D printers

Stepper motors are almost always included in common 3D printers. The use of stepper motors in 3D printers allows highly accurate motion and positioning without the need for encoders and other additional software or sensors in a cost-effective manner. Stepper motors can move to a known interval and then hold that position. They are a well-suited motor for moving objects to repeatable positions.

Depending on the type of printer, they are used in a variety of different applications. For example, stepper motors are used to move the extruder or build platform's X, Y and Z axes individually. The extruder assembly also has a stepper motor that is used to pull the filament into the extruder and control the delivery of consistent, even material to the machine throughout the printing process.

Stepper motors are available in a variety of sizes. the most common sizes used in 3D printers are NEMA 14, NEMA 17, NEMA 23 and NEMA 24.

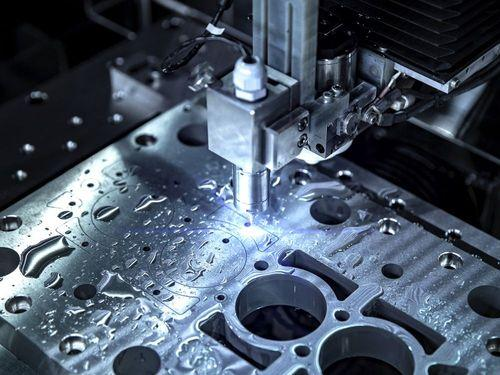

Stepper motors for CNC

Stepper motors for CNC

Stepper motors are an alternative to servo motors and can power most types of CNC machinery. Stepper motors have a small footprint and simple design, making them ideal for small applications such as CNC milling machines. Stepper motors do cost less than servo motors for the same power, but modern versions of stepper motors often have the same features. Stepper motors are easier to understand and operate because of the absence of encoders, and stepper motors are also brushless and easy to maintain.

Stepper motors can typically provide feed rates of 50 to 1,000 inches per minute, while servo motors can reach over 2,500 inches per minute. If you need very high accuracy and high production speeds, servo motors are a better choice.

For applications that don't require ultra-high precision. Most CNC milling machines that cost less than $25,000 use stepper motors rather than servo motors. Closed-loop stepper motors are also worth considering, they are good at preventing errors due to missed steps and can be a good choice when you need a budget friendly solution for expensive workpieces.

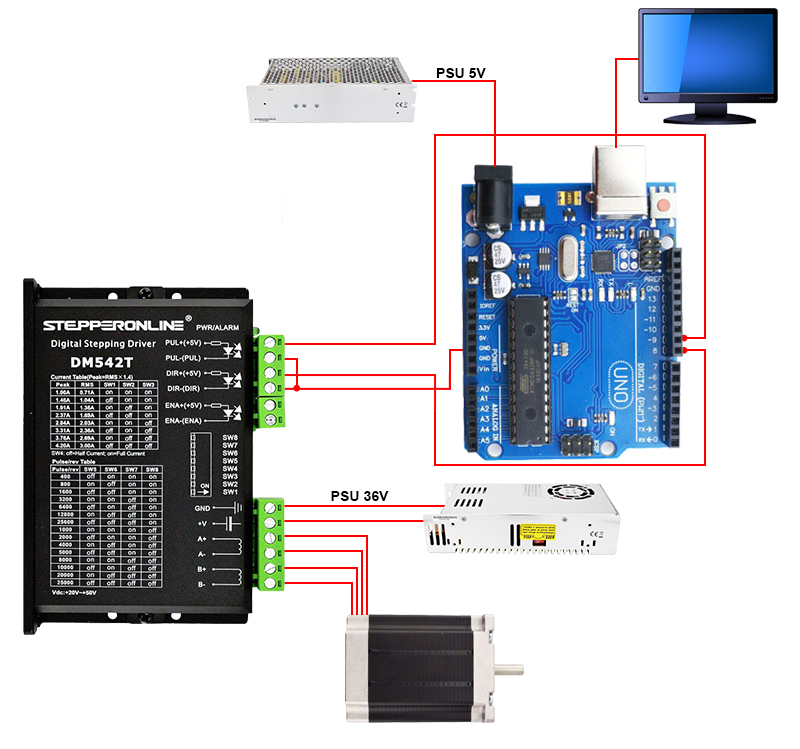

Stepper motors for Raspberry Pi, Arduino, MicroPython (e.g. pyboard, Wipy, ESP32, ESP8266 and MicroBit)

Stepper motors are an extremely common peripheral device used to add to single board computers such as the Raspberry Pi, arduino, etc, for hobbyists to teach themselves basic computer programming skills. It is often seen as a logical next step after learning to manipulate and control small, inexpensive stepper motors to learn to control LED on/off cycles and other simple switches or buzzer types.

There are many types of stepper motors available on STEPPERONLINE for such applications, starting with extremely inexpensive 5V versions that easily connect to the connectors on the Raspberry Pi's motherboard.

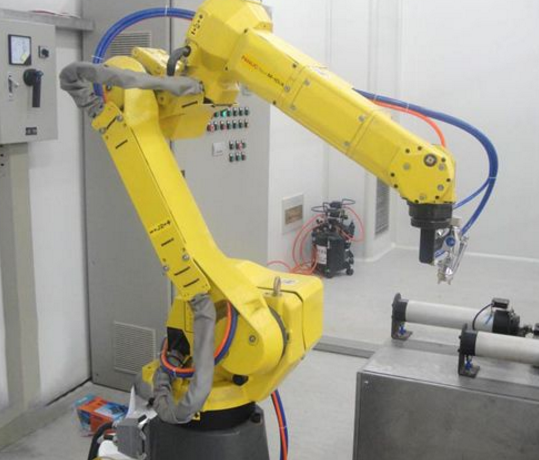

Stepper motors for robotics

Stepper motors can be used for motion control, acting as actuators that activate the robot joints and can accelerate the payload to the desired speed.

Stepper motors for cameras

Stepper motors have many applications in camera videography and are commonly used for autofocusing and zooming of cameras. Since the stepper motor brings smooth and high-precision driving ability, it allows it to minimize errors in the detection process and bring accurate and smooth focusing when combined with the latest live view technology.

Stepper motors for home improvement

Stepper motors also have many applications in the automation of the home. There are common uses of stepper motors to operate air conditioning blinds, open or close pipe valves, and drive motorized window shades.