Planetary gearboxes are gear units extensively applied in industrial drive technology for their compact design and versatile applications. Since planetary gears are not mounted in a stationary position, they perform orbital movements. This is why a planetary gearbox is also introduced an epicyclic gearbox.

Basics of planetary gearboxes

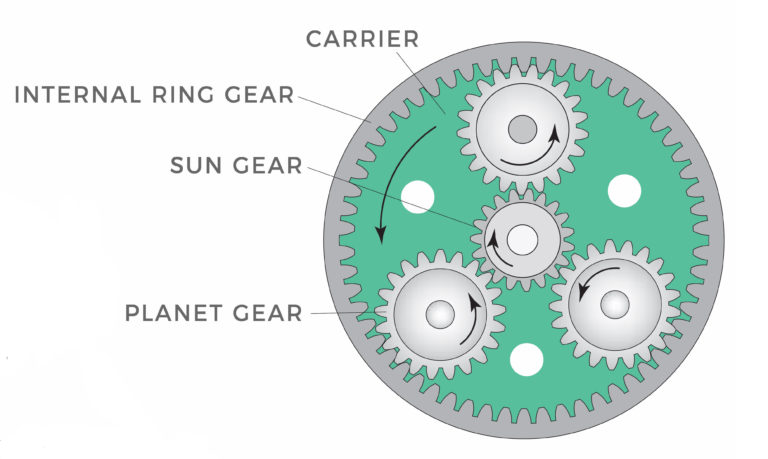

The planetary gearbox consists of a sun gear, planetary gears, a ring gear and a carrier. The input shaft drives the sun gear to rotate it. The planetary gears mesh with the sun gear and rotate on their axes as the sun gear rotates. The planetary gear also engages the stationary ring gear, causing the planetary gears to rotate around the sun gear. The carrier holds the planetary gears together and sets their spacing. It rotates with the planetary gears and combines with the output shaft.

The arrangement and trajectory of the gears can be compared to our planet-solar system, where the planets revolve around the sun, which is how the planetary gearbox got its name.

The number of planetary gears is not fixed, but in industrial applications, it is at least three. As the number of planetary gears increases, by distributing the load over a larger number of tooth meshes, the amount of torque that can be transmitted can be increased.

Characteristics of planetary gearboxes

Since planetary gearboxes contain multiple planetary gears, multiple teeth mesh simultaneously during operation. This power distribution ensures higher efficiency than other types of gears and therefore also allows higher transmittable torque with a more compact design.

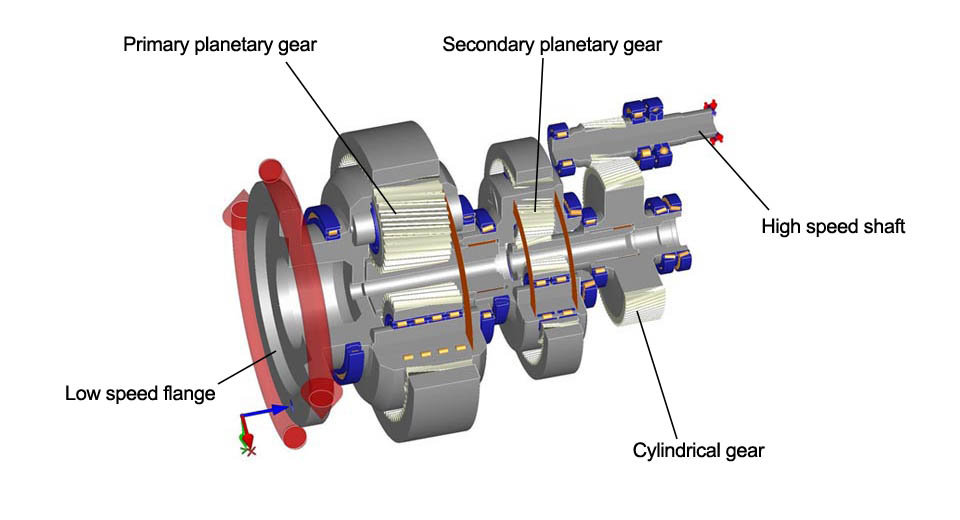

The gear ratio of a planetary gearbox is determined by the ratio between the ring gear and the sun gear. If the size of the ring gear remains the same, you can change the gear ratio by changing the number of teeth of the sun gear and the planetary gear. The smaller the sun gear you choose, the larger the gear ratio will be. In the mathematical discussion, the lowest gear ratio is 3:1 and the largest is 10:1. At ratios less than 3, the sun gear becomes too large for the planetary gears. The sun gear becomes too small and the torque decreases at ratios over 10. However, if higher ratios are required, several planetary gear sets can be arranged in succession in the same ring gear or in two fixed ring gears. Such a constellation is then called a multi-stage planetary gear. Planetary gearboxes are suitable for counterclockwise and clockwise rotation, as well as for continuous, alternating and intermittent operation.

Types of planetary gearboxes

1.Wheel drive

The sun gear drives the surrounding planetary gears which are held in a carrier in the wheel drive gearbox. The planetary gears make the outer ring gears rotate when the sun gear is driven. It is possible to mount the wheels on the housing of the gearbox. By mounting the wheels directly on the gearbox, the size of the assembly can be reduced to a minimum.

2.Shaft output

The sun gear drives surrounding planetary gears that are housed in a rotating carrier in a shaft drive gearbox. The gearbox housing is fixed directly to the machine with the output being a rotating shaft.

3.Spindle output

The working principle of the spindle output planetary gearbox is similar to that of the shaft output, although the output is provided as a flange.

Advantages of planetary gearboxes

Planetary gearboxes have coaxially aligned input and output shafts. This type of assembly means that planetary gearboxes are compact. They transmit high torque in a compact design, with high torque density and low backlash. The simple design is an efficient and effective way to transfer power from the motor to the output. Approximately 97% of the input energy is transferred as output. They can achieve high gear ratios that enable large speed reductions. They have appropriate stiffness and low noise. With better load distribution, they have a longer service life.

Grease or oil as lubricant in planetary gearboxes

Adding lubricant will reduce the incidence of planetary gearbox failures and extend the service life of the equipment. Despite how accurately a planetary gearbox is constructed and assembled, there are often rolling or sliding parts inside. If one planetary gear is closer to the sun gear than the other, then the planetary gears may experience some imbalance, leading to increased wear and failure. For this reason, every planetary gearbox includes a lubricant to keep the gears performing well and prevent wear, whether it's grease, oil or synthetic gel.

In addition, the compact footprint of planetary gears results in high heat dissipation, so applications that perform at very high speeds or experience sustained performance may require cooling. And lubricants always present a cooling effect and reduce noise or vibration.

Applications of planetary gearboxes

Planetary gearboxes are widely used in industrial applications for their many advantages. Planetary gears can handle speed and torque conversion in electrical systems and machines. Planetary gearboxes can be connected to any type of motors, such as servo motors, DC motors or stepper motors. As a matter of course, the use of planetary gears is not limited to industrial applications, they can be found in many fields. Some of the fields of application can be:

- Drives for robots

- Conveyor technology for conveyor belts

- Drives for machine tables

- Printing machines

- 3D printing

- Packaging machines

- Wheel drives

- Rail drives

- Slewing drives

- Hoist drives

- Mixing

- Winch drives

- Pumps

- Coil tubing injectors

- Auger and drilling drives

- Cutter head drives

- Wind turbines

- Robotic mowers

- Drives for operating tables in medical technology

- Security equipment

- Instrumentation

- Aerospace